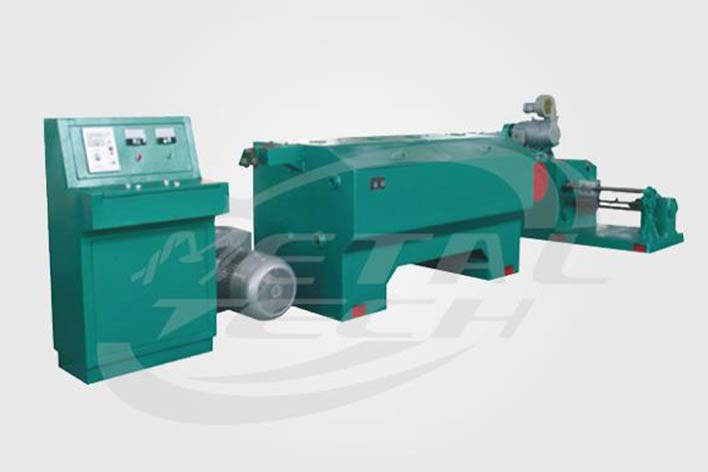

Wire drawing machine is also known as drawing machine or wire drawer, which is widely used in industrial applications.

Ⅰ.The classification of wire drawing machine for sale

Wire drawing machines can be divided into metal drawing machine, plastic drawing machines and bamboo drawing machines according to its application. In which, metal drawing machine for sale is our strength, we manufacturer aluminium wire making machine, copper drawing machine and stainless steel wire drawing machine.

Ⅱ. The selection guide of wire drawing machine for sale

1. Check the structure. Small and medium sized drawing machines generally needs high speed, which depends on whether the equipment body is a casting. If it's not a casting, there will be great vibration at high speed, and the machine can't be operated at a high speed. Because of the high cost of casting, its price is also higher.

2. Check the selection of bearings. The bearings of good quality wire drawing machine are made in Sweden or Germany, which can be used for three or four years.

3. The selection of tower wheel. Large factories generally choose the tower wheels of famous brand manufacturers, and the price will be relatively high because the quality of the spraying thickness of tower wheels produced by famous brand manufacturers will be guaranteed, which can not be seen by naked eyes. While the tower wheels produced by small factories has thinner spraying thickness, thus the processing cost will be much lower, and the service life will be much shorter.

4. Check the gears. The gear of medium wire drawing machines produced by large factory needs to be grinded, and the surface accuracy needs to reach the fifth level or more. The wire drawing machines produced by some manufacturers are not even gear hobbing, let alone gear grinding. The machines seem to become scattered after one year.

Metal Tech's straight line wire drawing machine, water drawing machine, pointing machine for wire drawing and automatic wire straightening and cutting machine are professional among many applications. Check if you have any interests.

Ⅲ. The maintenance of wire drawing machine

1. The daily maintenance

(1) keep the outside of the wire drawing machine clean, and check whether the gas supply pipeline and quick connector are in good condition.

(2) The upper and lower bearing seats and lifting screw should be lubricated.

(3) The water in the air filter should be discharged.

(4) The sand belt should be checked and the balance should be adjusted.

2. Weekly maintenance

(1) Clean the sludge left by daily maintenance, and carry out lubrication maintenance according to daily maintenance requirements.

(2) Check the conveyor belt of wire drawing machine and its tension (if the tension is too loose, please adjust it to moderate).

(3) Check the sand belt of wire drawing machine and its tension (if the tension is too loose, please adjust it to moderate).

EN

EN

fr

fr  es

es  ru

ru  pt

pt  ar

ar  vi

vi  th

th  pl

pl  ro

ro